A guide to applications of Vision AI: Surface defect detection

Radhika Madhavan

Director of Marketing

Table of Contents

- What is Vision AI?

- How does Vision AI work?

- Applications of Vision AI in various industries

- High Peak’s Vision AI is a versatile software solution that has proven to be effective in various industries

Missing tiny surface defects can lead to significant product failures and customer dissatisfaction. The global defect detection market is anticipated to reach USD 5.0 billion by 2026, growing at an annual rate of 7.5%. This highlights the increasing need for reliable surface defect detection solutions, ensuring product quality is more critical than ever.

Machine learning and computer vision technologies are meeting this demand. They are transforming industries by providing advanced capabilities for automated inspections and defect detection.

One such technology is High Peak’s Vision AI, a software solution that enhances surface defect detection.

Vision AI has proven to be effective in various industries, including retail, security, healthcare, construction, automotive, manufacturing, logistics, and agriculture.

What is Vision AI?

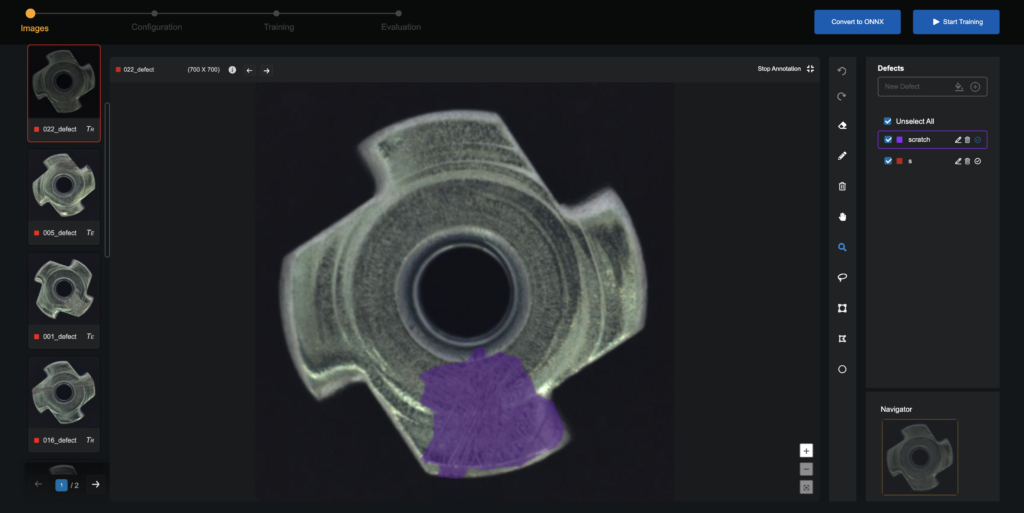

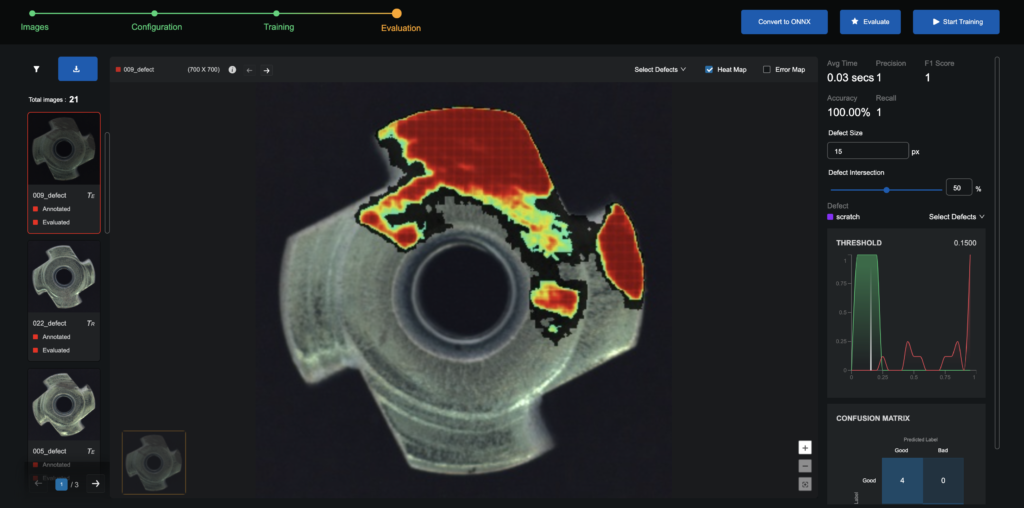

Vision AI is a software solution that utilizes machine learning and computer vision technologies to enhance surface defect detection. It is designed to analyze images and identify anomalies such as scratches, dents, and other imperfections on surfaces. The software uses deep learning models to recognize and classify these defects accurately.

How does Vision AI work?

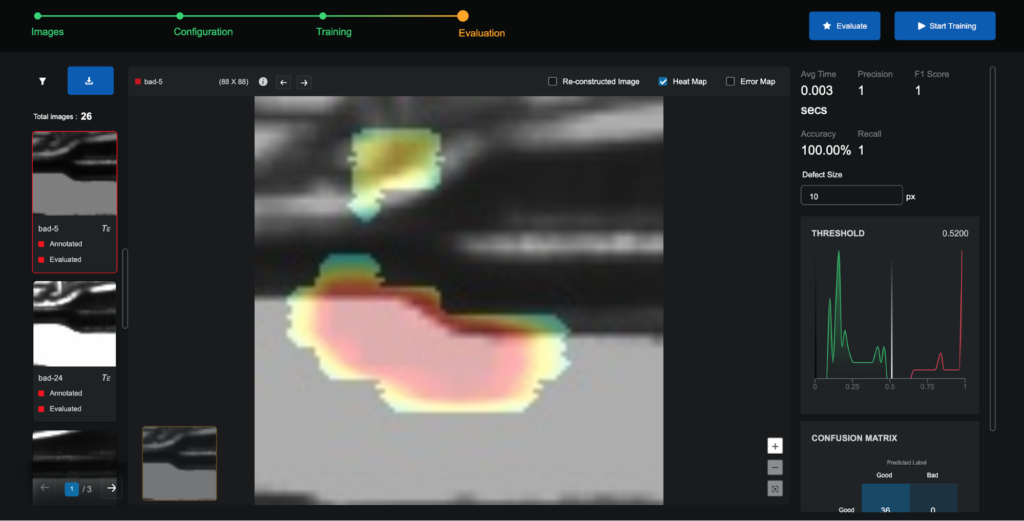

Vision AI works by analyzing images of surfaces to detect and classify defects. The surface defect detection software utilizes machine learning algorithms to train deep learning models on labeled data.

These models can then recognize and classify defects in images accurately. The surface defect detection software uses various computer vision techniques to analyze the images, including edge detection, corner detection, and feature detection.

Once the images are analyzed, the software can automatically classify the defects into different categories based on their type and severity. The software can also provide real-time analysis of images, making it ideal for use in production environments where time is of the essence.

Applications of Vision AI in various industries

In this guide, we’ll explore the different applications of Vision AI in these industries. Also, see how this surface defect detection software is helping companies enhance quality control, reduce downtime, and minimize costs associated with repairs and warranty claims.

Automotive industry

The automotive industry has benefited significantly from the use of Vision AI. This surface defect detection software can detect surface defects in real-time, helping manufacturers identify issues in the production process, such as issues with car panels, tires, and windshields. The software can detect various defects, including scratches, dents, and other anomalies that would be difficult to detect manually. Vision AI can also automatically classify defects, helping manufacturers quickly identify the root cause of the issue and take corrective action.

- Real-time defect detection for improved quality control

- Automated classification of defects for quick identification and corrective action

- Reduced downtime and increased productivity through faster defect identification

Manufacturing industry

In the manufacturing industry, this surface defect detection software can help to identify defects in products that would be difficult to identify with the naked eye. Vision AI can identify surface defects, such as scratches, cracks, and dents, as well as more complex issues, such as misaligned components and missing parts. Our surface defect detection software can also identify potential issues before they become more significant problems, improving the quality of the end product.

- Detection of complex issues that would be difficult to identify manually

- Early detection of potential issues for improved product quality

- Reduced costs associated with repairs and warranty claims

Healthcare industry

In the healthcare industry, Vision AI can detect defects in medical equipment, ensuring that patients receive the highest quality care. The surface defect detection software can identify surface defects, such as scratches and marks, as well as more complex issues, such as misaligned components and missing parts. Vision AI can also identify potential issues before they become more significant problems, improving the safety and efficacy of medical devices.

- Improved safety through the detection of defects that can compromise medical equipment integrity

- Early detection of potential issues for improved patient safety

- Reduced costs associated with repairs and warranty claims

Retail industry

In the retail industry, Vision AI can help to improve the quality of products and enhance the shopping experience for customers. Our surface defect detection software can detect defects in products, such as scratches, dents, and other anomalies, ensuring that customers receive high-quality products. The software can also identify issues with packaging, ensuring that products are properly protected during shipping.

- Improved product quality control and customer satisfaction

- Reduced costs associated with repairs and returns

- Early detection of potential issues for improved product safety

Security industry

In the security industry, Vision AI can detect potential threats and suspicious activities in real-time. Our surface anomaly detection software can identify anomalies. These include unattended bags, suspicious behavior, and unauthorized access. Thus helping to improve security measures and prevent potential security breaches.

- Enhanced security measures through real-time anomaly detection

- Improved safety and security for individuals and facilities

- Early detection of potential threats for improved preparedness

Construction industry

In the construction industry, Vision AI can help to improve safety and reduce downtime by detecting defects in construction materials and equipment. The surface defect detection software can identify surface defects, such as cracks and chips, as well as more complex issues, such as misaligned components and missing parts. Vision AI can also identify potential issues before they become more significant problems, improving the safety of construction sites.

- Improved safety through the detection of defects that can compromise construction equipment integrity

- Early detection of potential issues for improved productivity and reduced downtime

- Reduced costs associated with repairs and warranty claims

Logistics industry

In the logistics industry, Vision AI can help to improve efficiency and reduce costs by automating inspections and identifying defects in products and packaging. The surface defect detection software can detect surface defects, such as scratches and marks, as well as more complex issues, such as misaligned components and missing parts. Vision AI can also automatically classify defects, helping logistics companies quickly identify the root cause of the issue and take corrective action.

- Improved efficiency through automated inspections and defect detection

- Reduced costs associated with repairs and returns

- Automated defect classification for quick identification and corrective action

Agriculture industry

In the agriculture industry, Vision AI can help farmers identify issues with crops and plants, ensuring that they receive the necessary care and attention. The surface defect detection software can detect issues with plant health, such as disease and nutrient deficiencies, as well as issues with crop growth, such as pests and water stress. Vision AI can also provide farmers with real-time data, allowing them to make informed decisions about crop management.

- Improved crop management through real-time data and anomaly detection

- Enhanced plant health and productivity through early detection of potential issues

- Reduced costs associated with crop loss and damage

High Peak’s Vision AI is a versatile software solution that has proven to be effective in various industries

These industries include retail, security, healthcare, construction, automotive, manufacturing, logistics, and agriculture. By automating inspections and identifying defects in real-time, Vision AI is helping companies to enhance quality control, reduce downtime, and minimize costs associated with repairs and warranty claims. As technology continues to evolve, it’s clear that Vision AI will play an increasingly important role in improving product quality and enhancing safety and security across various industries.